DIY!!

Don’t forget to check out Luke’s channel found here https://www.youtube.com/channel/UC1E8OmOG17VckoPviOPmkMw

If you want to have a look at those special videos become a member and join by clicking this link https://www.youtube.com/channel/UC4AkVj-qnJxNtKuz3rkq16A/join

Don’t forget that you can buy my books and materials for your own experiments including our conductive inks at https://secure.workingink.co.uk/working-ink-shop/ – and for the many who have asked, yes, you can also donate to further our work, again through the shop.

I hear axial flux and I think of Cedric Lynch and his AGNI/Lynch motor which is used as a generator and a very efficient high torque but low rpm motor. Here is some more information if you’re interested, it’s a little dated but still applicable:

The Lynch motor is an unconventional design with a disc armature. It marries the advantages of a conventional, wound armature motor with the benefits of a flat (printed circuit) motor. It is similar to a pancake motor, but is more powerful than any of these technologies. The disc armature has magnets on both sides, doubling the available flux density and shortening the magnetic path. It therefore packs more power per pound and per cubic inch than any other motor technology. Of course such a revolutionary motor is not for every application – it is not as cheap as wound field motors, but for many applications it is a far superior motor. It has a previously unheard of power to weight ratio and also power to volume ratio. It is also highly efficient because of the double magnet design and associated short magnetic path. It also includes integral fan cooling.

The Lynch motor is an important development which spurred other motor designers to improve their products to remain competitive, such as synchronus permanent magnet machines. As a result of the competition between manufacturers the cost of high performance motors and controllers has fallen dramatically. We hope the cost of solar cells also reduces to allow renewable transportation to develop as a viable alternative to carbon fuels.

Cedric Lynch built his electric bike around a mid-drive configuration, also building one of the worlds most efficient light weight electric motors to power his rig reliably at 60-MPH for significant distances. He would later set several world records with his axial flux motor and bring it to market as the Lynch / Agni motor. Briggs and Stratton would eventually buy this technology which would lead to the Etek motor, which is now famous for making high speed efficient electric hot rods.

Cedric uses to achieve high speeds is by following the rules of aerodynamics, and building a bike that is as aerodynamic and as efficient as possible. The other builders on this list bypassed this step, and Cedric uses this bicycle as daily transportation on real commutes. Although this high-efficiency motor uses “old school” brushes, this fact allows builders to use very affordable controllers. He has proven his design choices through thousands of miles of commuting, and the Lynch motor is highly respected.

Cedric Lynch is known as the creator of the Agni Motor, a highly efficient electric motor that weighs around 25 pounds and can put out as much as 50hp.

Cedric Lynch is a British ‘mad scientist’ type mechanical engineer obsessed with the idea of greener transportation. His interest has been in building a super efficient yet powerful vehicle that can serve as a car replacement.

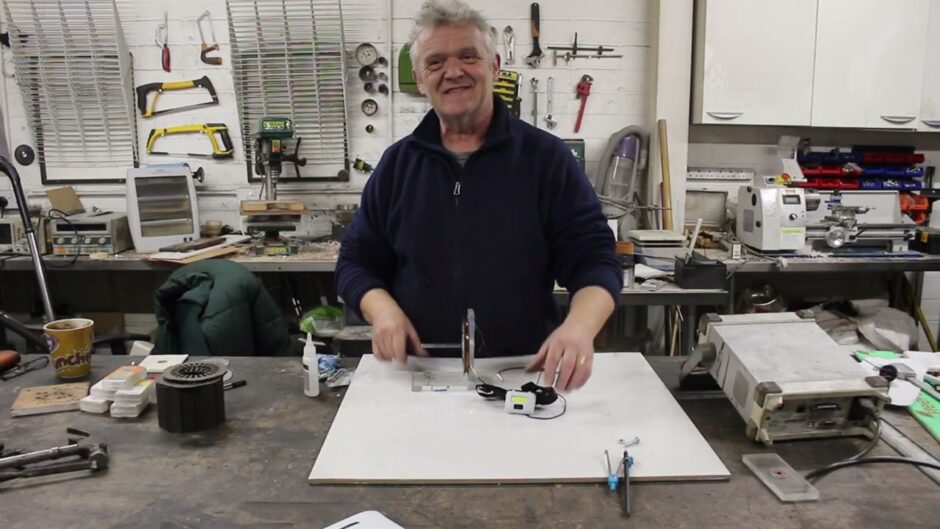

He started thinking of his own design for an electric motor in 1983 when he began entering competitions organized by the Battery Vehicle Society regarding building an efficient electric vehicle. At the time there was no reasonably priced DC motor with descent efficiency so Lynch decided to build his own utilizing modifying existing motors with old tin cans that he would spread out flat to use as cooling fins. Surprisingly using rudimentary materials and a garage work bench, Cedric was making better more efficient electric motors than any of the universities were able to manufacture in state of the art workshops.

Cedric then came up with a motor design that could be cheaply manufactured and began manufacturing his own motor that he could sell to the public in 1988 and the Lynch Electric Motor Company was born, known as LEMCO.

Cedric first used his motor to create a small boat called “The Spark” that would set an electric boat efficiency record. From there Cedric turned his attention to bicycles, an application generally considered too small for a lynch motor at that time. Cedric mounted his motor in recumbent bike, allowing him space to eventually use a set of thundersky lithium batteries.

The resulting aerodynamic recumbent bike had a top speed of 60mph and still managed an incredible range of 150 miles. Cedric rode his recumbent creation everywhere as a daily commuter, putting an amazing 50,000 miles on the machine – technically a motorbike.

Briggs and Stratton, the US firm famous for lawn mower engines, bought the technology and used it in their E-Tech Motor, and Cedric went on to manufacture his latest incarnation of his lynch design into the Agni motor, which is used in go karts, sailboats, motor boats, and even small airplanes.

The Lynch designed motors all have the same traits. Brushed motors, around 25 pounds in weight and they are able to put out enormous power compared to their weight. Sometimes as high as 50 hp (depending on amperage ran through the motor) at an incredible 98% efficiency. Lynch Motors are also the most often used motors in electric motorcycle racing applications.

Cedric’s zero-emission motorcycle, which has a top speed of 120mph, was shown in action winning the world’s first zero carbon race – the TTxGP in the Isle of Mann.

The idea for the electric motor has been snapped up by the 56-year-old’’s friend Arvind Rabadia, who together with his brother Hasmuk Rabadia had been thinking of starting a business in India. They have now set up Agni Motors to make further-improved versions of Cedric’s motors

Despite Cedric’s breakthrough invention he has no formal engineering qualifications and taught himself the techniques needed to construct his engine. He first became interested in electrics when his parents bought him a book entitled How to build things from things found at home.

The Etek motor is a brushed 25-pound pancake shaped motor that puts out enormous power for its weight. Depending on amperage and voltage the Etek can easily provide between 15-horsepower and 30-horsepower reliably and consistently (11-kW / 22-kW). A perfect platform for a powerful electric bike if you do not mind the weight. Although brushless motors are considered more modern, a brushed motor like the Etek allows the builder to use very affordable controllers.

Cedric-Lynch invented the motor and sold it to Briggs and Stratton which US company produced the Etek at a lower price (around $600). In the late 90’s early 2000’s it was the way to go for a high-power / light-weight electric vehicle. Many small E-vehicle records were set using the Etek motor. Finally, the market had a relatively lightweight and powerful electric motor available to the masses.

In essence, the Etek allowed hot rodders to build electric bikes. Before the Etek very few people had ever achieved 50mph on an electric bike. Even today, Etek motors (and newer incarnations of the Etek motor) are used to make some super fast electric bikes. In the case of Liveforphysics, the fastest E-bikes ever.

Liveforphysics used a newer version of the Etek (the Agni motor), to achieve speeds of over 70mph, and dominate a recent hill-climb event.

Every Etek I have ever ridden has been characterized by brutal off-the-line acceleration, usually to a point where you have to apply the throttle very carefully or get thrown off. However, it is possible to run an Etek at a lower voltage or lower amperage and have a very manageable, safe, and sane electric bike that will not burn out on you, no matter high steep the incline.

I just love how inventive you are. I’m in awe. I am fascinated by everything you do. I hope you’re going to build the bigger generator soon, I hope it works and I hope you will issue some instructions for people as useless at all things electrical as I… Thanks Roger!

I absolutely love how genuinely exited you get Robert when you build something. You are an inspiration to us all. The fact that you get so much joy from what you do is brilliant. You are like a big kid. Just like we all are too.

Unique design that makes winding a coil for it very easy! I would be interesting to see how well it runs as a motor.

That’s so awesome!! Can’t wait to see the bigger version! Thanks for everything you do, Robert!

@Rob, LOVE THIS… perfect timing too… I’m definitely going to give this one a go, with my own twist of course. Keep the hits coming Rob!

That’s really impressive how much it’s outputting and so simply made… brilliant idea as always !!!

This is one of the more unique axial flux generators I’ve seen. It’s Brilliant. I love the one coil idea. It’s even simplet than a serpentine coil seen in some other axial flux generators. Thank you. my mind is racing on addition improvement possibilities.

To get even better performance, you might like to reduce the magnetic reluctance with an iron core inside the copper coil by using a band of steel strapping that’s typically used for securing heavy things to pallets for shipping. I’d be very interested in if it still works with steel strapping on the outside of the coils, and if it might differ in performance from using steel strapping on the inside. A tape of Electrical steel with low magnetic retentivity would be even better but might be hard to find or may be expensive, where as steel strapping is cheap and abundantly available and will work well, but not as great.

Obviously your alternator will work as you demonstrated. But I see one self limiting downside. Under heavy load, the coil will have higher current flowing that in turn creates its own magnetic field (back emf) opposing the initial magnetic field from the magnets, and given the length of each tooth, it gets easyer to eject some of magnets magnetic fields from the teath leading to higher unused stray magnetic flux. Yes, pretty much every generator deals with this, but I think it will be more so here.

Thank you so much for publishing this one, Robert! You sparked an idea that I just had about leveraging the power of 3D printing and SelectiveLaserSyntering to potentially create altered npn/pnp bias’s in the actual metallic windings of the coil itself to further exploit the magnetic fields. Do you have any thoughts on whether this is plausible or too far down the rabbit hole?

Try to close the magnetic circuit, i.e. insert an iron core (short tube) connecting those two iron discs and then wind the coil tightly around it. You may get better induction. Also, longer magnets would give you more than 5mm to wind more turns on the coil, without diminishing the magnetic field. For example, using two magnets at a time, back to back, will at the same time strengthen the field. It is an easier construction than making several layers of the whole thing.